- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Variables in Ball Mill Operation | Paul O. Abbe®

Ball mill operation is often regarded as something of a mystery for several reasons. Ball milling is not an art it's just physics. The first problem will ball mills is that we cannot see what is occurring in the mill. The other problem is that many of the independent variables .

MACHINING OPERATIONS AND MACHINE TOOLS

3. Milling • Milling – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End ...

DESIGN, MODELLING AND ANALYSIS OF A 3 STAGE EPICYCLIC ...

capacity and compactness to gear drives. There is a wide variety of different combinations of planetary gear arrangements. For simple, ... lot of gears on an N/C milling machine with a form cutter or ball end mill, one should not consider making a 100piece lot of epicyclic carriers on an N/C mill.

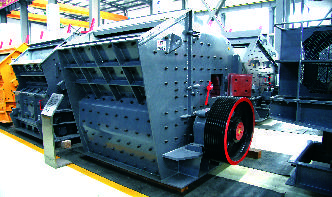

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

calculation for ball mill drive

drive calculation for a ball mill uk drive calculation for a ball mill. Calculation For Ball Mill Drive The mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 ston per hour This type twocompartment mill is a state oftheart shell supported cement finish mill ...

Formulas for gear calculation

Formulas for gear calculation – external gears Contents: Relationship between the involute elements Determination of base tooth thickness from a known thickness and viceversa. Cylindrical spur gears with standard profile Cylindrical spur gears with corrected profile • Without centre distance variation • With centre distance variation

Design Manual for Power Transmission Belts

This manual covers Vbelt drives used primarily for power transmission in industrial appliions. One or more Vbelts may be used on a drive, as required, to transmit the horsepower load. In general, the drives are in the integralhorsepower class as distinguished from light duty or fractional horsepower drives.

Technical Manual VBelt Drives

methods for the design and calculation of drives with Optibelt Vbelts and Vgrooved pulleys for industrial appliions. Our Appliion Technology experts offer you free support service regarding the appliion of our products and also help ... Power Transmission ...

Ball Mill Drive – Shanthi Gears

Address 304A, Shanthi Gears Road, Singanallur, Coimbatore – 641 005, Tamil Nadu, India. Phone No +91 422 . Fax +91 422

SOPHISTICATED RING GEARED MILL DRIVES: FEATURES AND ...

ABB mill drive is very network friendly. Motor torque Motor speed Network current Figure 5. Calculated network current during start/stop sequence. Operation Area As soon as the cascading of load has been detected and the mill runs stable, the mill controller releases the drive to ramp up to the customer speed reference received from DCS.

Gear unit that perfectly fits your ball mill | FL

One side drive provides a power range up to approximately 8,000 kW when engaged with the girth gear of your ball mill. In dual arrangement, with one gear unit on either side of the mill, our MAAG® LGDX gear unit covers grinding appliions up to 14,000 kW. Product features. Reliable gear unit components for a complete, adaptable side drive.

How to install and align the girth gear and pinion | prmdrive

· The central transmission adopts a highspeed planetary reducer, which is safe and reliable, with a service life of up to 10 years, low maintenance cost, but large onetime investment. The cost of edge drive is low, but the pinion needs to be replaced every 25 years. Edge drive is mainly used in coal mills and mills with small power.

Industrial gear unit drive solution for ball mills | SEW ...

Our drive solutions from perfectly compatible components (from the industrial gear unit through to the girth gear) provide the necessary power. Flexible drive solutions for use in ball mills A ball mill is a horizontal cylinder filled with steel balls or the like.

DESIGN, MODELLING AND ANALYSIS OF A 3 STAGE EPICYCLIC ...

capacity and compactness to gear drives. There is a wide variety of different combinations of planetary gear arrangements. For simple, ... lot of gears on an N/C milling machine with a form cutter or ball end mill, one should not consider making a .

GEAR COUPLINGGEAR COUPLING

Select a gear coupling to connect a 500 HP, 1170 RPM electric motor ... TUBE, ROD AND BALL MILLS Reducer, with final drive Machined Spur Gears Single Helical or ... Mills only Coke Plants Pusher Ram Drive Door Opener Pusher or Larry Car Traction Drive ...

Motor Drive For Ball Mill

Motor Power To Drive Ball Mill. Motor Power To Drive Ball Mill. Figure 9 shows the milldrill with the existing cnc xaxis on the left end of the tablehe yaxis has now been fitted with the rebored driven timing pulley instead of the handwheeligures 10 and 11 show closeups of the yaxis timing pulley before mounting the motor.

Gear Train : Gear Ratio, Torque and Speed Calculations ...

Step3: By Multiplying gearratio between 1 to 2 and 2 to 3. We will get resultant GR between Driver and Driven Gear. Resultant Multi Gear Train GR = 0. 5 × = From the above, calculated gear ratio we can calculate the speed and torque at output gear.

Copyright © .CMichineAll rights reserved.خريطة الموقع