- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Coal Pulverizer Design Upgrades to Meet the Demands of Low ...

Coal pulverizer design and operation is an important element integral to the long term success of Low NOX combustion systems. The increased use of Low NOX burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous emissions (NO CO, HC) and .

coal pulverizer design pdf

Improving Coal Pulverizer Performance and Reliability. type coal pulverizer In this design the grinding rolls are stationary while the ring or bowl as it is sometimes called is rotated by a worm gear drive Powerful springs force the grinding rolls against the ring providing the pressure required to pulverize the coal Raw coal enters the top of the pulverizer through the raw coal feed pipe The raw

Pulverizer

· A pulverizer can automatically transfer items out of any sides that directly correspond to one of its output slots. This is called autooutput. It can also transfer items from adjacent inventories into any sides that directly correspond to its input slot. This is called autoinput. Autooutput and autoinput occur whenever the machine finishes processing an item, or .

Pulverised Coal

The heart of a pulverized coalfired boiler is the pulverizer, also known as the mill. Depending on speed pulverizers are classified as lowspeed, mediumspeed, and highspeed mills. Pulverized coal burners may be loed on the front or opposed walls or in the corners of the furnace. There are two types of fuelfiring systems: bin system and directfiring system. Coal feeders are either the ...

Coal mill pulverizer in thermal power plants

· pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner panels.

Types of Boiler Coal Pulverizers

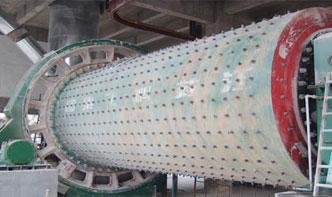

· Harder coals require this type of pulverizers. 2. Impact and Attrition Type. Coal is fed into a rotating cylinder containing steel balls of around 50 mm diameter. When the cylinder rotates, the balls rotate along with the cylinder and fall down when they reach the top position. Coal is ground due to attrition and impact. Coal feeds into the ...

best design of coal pulveriser somalia

Best Design Of Coal Pulverizer In India 2016. Coal Pulverizer at Best Price in India Coal pulverizer is one advanced mill adopting top technology domestic and abroad and based on many years mill experiences it can crush dry grind and classify the materials coal pulverizer can be widely used in such industries as . More Details >

Eskom designveteran pinpoints Medupi, Kusile faults ...

· Eskom designveteran pinpoints Medupi, Kusile faults. CAPE TOWN — A veteran former Eskom power station designer has diagnosed the main problem and suggested a fix for Medupi and Kusile power stations, now several years beyond their completion dates and costing the nation more than R300bn extra . Alex Ham was Chief Engineer, Power Station ...

Coal Pulverizer – Power Plant | Pall Corporation

Many coal pulverizer designs do not incorporate any filtration in their lube circuits. The pulverizers that do not incorporate filtration use coarse filtration such as 40micron cleanable mesh or 200micron cleanable, stacked disk filters. Such OEMsupplied filtration is often unable to keep up with the inherently high ingression rate. This results in contamination levels often exceeding ISO ...

mathematical model of coal pulverizer

Mathematical Model Of Coal Pulverizer. performance analysis of natural ray coal seam thickness,the technology of coalrock interface recognition is the core of realizing the automatic heightening technology of shearers rocker. only by accurately and quickly identifying the interface of coal and rock can we realize the fully automatic control of shearer. as the only one used in .

best design of coal pulveriser

best design of coal pulveriser ; Latest Projects. K Series Mobile Crushing Plant. K Series Portable Crusher Plant, also known as K Series Portable Crusher, Crawler Mobile Crusher. Crawler Mobile Crusher is a fully hydraulic tracktype mobile crusher developed and completed in order to satisfy higher user demands. Mobile Vibrating Screen . Mobile Vibrating Screen is equipment providing ...

Advanced Development of Pulverized Coal Firing Technologies

weight flow ratio of primary air to pulverized coal) burners designed for the combustion of dried lignite coal. We have already reported on our burners for single firing of semi anthracite coal and of oil coke in previous reports.(2), (3) 2 Vol. 44 No. 2 2011 ADF burners Subbituminous coals and other socalled "lowrank" coals are increasingly being used to meet needs to reduce the ...

Materials Industries

As specialists in the design, manufacture, and commissioning of pulverizing systems for fine and semifine grinding, Bradley Pulverizer has equipment operating across six continents in a variety of industries and appliions. Producers of ores, coal, clays, cement, fertilizers and many other minerals rely on Bradley mills for uninterrupted heavy tonnage production of materials which .

Advanced Development of Pulverized Coal Firing Technologies

weight flow ratio of primary air to pulverized coal) burners designed for the combustion of dried lignite coal. We have already reported on our burners for single firing of semi anthracite coal and of oil coke in previous reports.(2), (3) 2 Vol. 44 No. 2 2011 ADF burners Subbituminous coals and other socalled "lowrank" coals are increasingly being used to meet needs to .

Pulverized Coal Pipe Testing and Balancing

· The isokinetic coal sampling method, although more difficult, is the best option for determining the true mill coal fineness produced and to calculate pulverizer performance. We perform isokinetic ...

A Comparison of Three Types of Coal Pulverizers

This paper presents a comparison of the Riley Vertical Roller Mill with Riley's two other pulverizer designs— a lowspeed ball tube mill and a highspeed attrition pulverizer. Specific topics include throughput capability, fuel type, availability, reliability, power consumption, product fineness, coal drying capability, feed size re quirements and appliion data. INTRODUCTION Since the ...

Pulverizers 101: Part I

· Pulverizers 101: Part I. Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal .

Khalsa Coal Pulverizing Plants – Khalsa Coal Pulverizer ...

About Khalsa Coal Pulverizer. Surindra Engineering* a KHALSA Group Company, has been designing, manufacturing and serving Steel rolling mills, Coal Pulverizing Plants, Coal Pulverizers, Coal hammer mills and associated auxiliary equipment for over 35 years for the steel industry markets.

Mitsubishi Power | Pulverizers

A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal several centimeters in diameter down to fine particles. The pulverizer includes pulverization, drying and classifiion functions. The classifiion function plays the important role of ensuring that only fine particles are sent to the boiler.

Best Design Of Coal Pulveriser

Best Design Of Coal Pulveriser. As one of the worlds leading coal pulverizer manufacturers, Williams has the most advanced direct fired coal and pet coke pulverizing system in the field today. Design features of our coal pulverizer emphasize improved system reliability, constant product size control, and reduced energy requirements. Send Email: [email protected] Comment Chat Online. Blog ...

best design of coal pulveriser crusherasia

best design of coal pulveriser crusherasia. Our products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials leading products have crushing equipment, sand making equipment, mobile crusher, etc., Each type of product is with complete specifiions. All products have passed .

best design of coal pulveriser

COAL PULVERIZER DESIGN UPGRADES TO MEET THE . The design "capacity" of the same pulverizer will grind 135,000 pounds per hour with fuel that is 55 HGI (Hardgrove Grindability Index) coal, ¾" raw coal top size, 7% moisture and produces pulverized coal that is 70% passing 200 mesh fineness (red line).

Khalsa Group Company | Khalsa Coal ...

About Khalsa Coal Pulverizer. Surindra Engineering* a KHALSA Group Company, has been designing, manufacturing and serving Steel rolling mills, Coal Pulverizing Plants, Coal Pulverizers, Coal hammer mills and associated auxiliary equipment for over 35 years for the steel industry markets.

Pulverised Coal

The heart of a pulverized coalfired boiler is the pulverizer, also known as the mill. Depending on speed pulverizers are classified as lowspeed, mediumspeed, and highspeed mills. Pulverized coal burners may be loed on the front or opposed walls or in the corners of the furnace. There are two types of fuelfiring systems: bin system and directfiring system. Coal feeders are .

Copyright © .CMichineAll rights reserved.خريطة الموقع