- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Ball End Mills

Also known as ballnose end mills, they are rotated against a workpiece to make roundbottomed slots and pockets or mill complex shapes without sharp corners. Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece. End mills are used on CNC or manual milling machines.

12 Tile Manufacturing/Production Process StepbyStep | A ...

The Primary raw material for the tile production is Clay, Quarts and Feldspar. ... The stain can be directly added on Ball milling. In other method desired amount of glaze is taken in drum, then stains are added to it and then it is mixed. Engobe is also prepared in the same method. Appliion of Engobe and Glaze.

Encyclopedia Britannica | Britannica

Informative and lively, Show What You Know is a quiz show for curious tweens and their grownups from Encyclopædia Britannica. Hosted by author Christopher Lloyd, each episode gives three middlegrade contestants a chance to go head to head with questions about the earth, the universe, ancient history, and more from the Britannica All New Kids' Encyclopedia: What We Know What We Don't.

Basic End Mills Technical Information | MSC Industrial ...

End Mills are used for making shapes and holes in a workpiece during milling, profiling, contouring, slotting, counterboring, drilling and reaming appliions. They are designed with cutting teeth on the face and edge of the body and can be used to cut a variety of materials in several directions.

Milling Process, Defects, Equipment

End milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified feature, such as a profile, slot, pocket, or even a complex surface depth of the feature may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passes.

Ball Valve

Ball Valve How They Work. Figure 1: Ball valve sectional view. A ball valve is a shut off valve that controls the flow of a liquid or gas by means of a rotary ball having a bore. By rotating the ball a quarter turn (90 degrees) around its axis, the medium can flow through or is blocked. They are characterized by a long service life and ...

Urgent Care vs. Primary Care Doctor

22/09/2021 · Urgent Care vs. Primary Care Have Different Purposes. Your primary doctor plays a very important part in your long term health. PCPs know your medical history and the conditions you've suffered from. They have access to your medical records and can therefore come to more edued conclusions when you come to them with symptoms.

12 Tile Manufacturing/Production Process ...

The Primary raw material for the tile production is Clay, Quarts and Feldspar. ... The stain can be directly added on Ball milling. In other method desired amount of glaze is taken in drum, then stains are added to it and then it is mixed. Engobe is also prepared in the same method. Appliion of Engobe and Glaze.

How ceramic tile is made

Roller or cone type crushers can also be used. A third particle size reduction step may be necessary. Tumbling types of mills are used in combination with grinding media. One of the most common types of such mills is the ball mill, which consists of large rotating cylinders partially filled with spherical grinding media.

Virtual lab

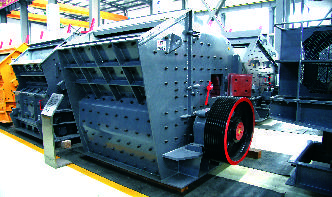

Jaw crusher. Rotary dryer. can crush materials with size smaller than 500 mm. Impact crusher. Ball mill. Rotary dryer. Jaw crusher. is used as primary secondary crushing equipment to crush material with compression strength less than 320MPa: Impact crusher.

MILLING OPERATIONS TYPES OF MILLING MACHINES

milling cutter has teeth on both sides and on the periphery. When teeth are added to one side only, the cutter is called a halfside milling cutter and is identified as being either a righthand or lefthand cutter. Side milling cutters are generally used for slotting and straddle milling. Interlocking tooth side milling cutters and staggered tooth

Milling Finish: Complete Guide [ Tips, Techniques, and ...

You shouldn't use a 4 flute cutter when slotting in aluminum (there isn't enough chip clearance), but you can use a 3 flute to slot and it is equivalent to 50% more rpm than the 2 flute. Even better, if you are milling around the outside profile (peripheral milling), there may be plenty of clearance for chips to fall away and you could use a 4 flute cutter on aluminum.

Porcelain Enameling Effluent Guidelines

13/07/2021 · A water solution of nickel salts is used in nickel flash operations in the steel subegory. The ball milling operation uses water for washing out the ball mills between mixing batches and for cooling the ball mills. During appliion of the porcelain enamel slip, water may be used as a curtain device for entrapping waste slip from overspray.

Primary Clarifiers

Detention Time About 50% of a municipal type suspended solids will settle out in 30 minutes, about 60% after 1 hour, and about 70% after 2 hours. Usually, clarifier design allows for detention times ranging between 2 to 3 hours, however, it may be as long as 4 to 5 hours. If necessary use a settleometer to check how long solids can be in the ...

Ball Mills

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Introduction to Tensile Testing

Introduction to Tensile Testing / 5 Fig. 6 The lowstrain region of the stressstrain curve for a ductile material tic contribution and e e is the elastic contribution (and still related to the stress by Eq 3). It is tempting to define an elastic limit as the stress at which plastic deformation first occurs

Mill (grinding)

Industrial ball mills can be as large as m (28 ft) in diameter with a 22 MW motor, drawing approximately % of the total world's power (see List of countries by electricity consumption). However, small versions of ball mills can be found in laboratories where they are used for grinding sample material for quality assurance.

Ball Valve

Ball valves consist of a spherical obturator with a cylindrical hole, usually of the same diameter as the pipe, although it can be smaller. Operation is by rotation (1/4 turn) of a shaft mounted, often horizontally, with its axis at right angles to the cylindrical hole. Seals are usually resilient and can provide drop tight shut off.

Different Types of Lathe Cutting Tools for Turning, Boring ...

23/06/2020 · The chamfering tool is used to create a bevel or furrow on the part. A chamfer can be used to smooth sharp or hazardous edges on a workpiece. 4. Knurling Tool. Knurling tools are used to produce knurled lathe parts, through creating or pressing a pattern onto a round section, used as a grip for a handle, also usually created on fasteners like nuts.

Ball Valve

Ball valves consist of a spherical obturator with a cylindrical hole, usually of the same diameter as the pipe, although it can be smaller. Operation is by rotation (1/4 turn) of a shaft mounted, often horizontally, with its axis at right angles to the cylindrical hole. Seals are usually resilient and can .

Google Translate

Google's free service instantly translates words, phrases, and web pages between English and over 100 other languages.

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

AG Mill + Ball Mill + Crusher (ABC Circuit) This can be used to correct a too coarse product from the primary mill. Mostly operated wet, but also dry possible. AG Mill + Pebble Mill. Two stage AGgrinding with the primary mill in open circuit and the .

SAG Mill | Autogenous and SemiAutogenous Mills | FL

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach. When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. FullerTraylor SAG/AG Mills range in size from through in diameter with powers as high as 28,000 kW.

Spain: Excessive use of force by National Police and Civil ...

3/10/2017 · Press Release October 3, 2017 1:02 pm Spain: Excessive use of force by National Police and Civil Guard in Catalonia. Amnesty International has directly confirmed on the ground that members of the National Police force's Police Intervention Unit (UIP) and Civil Guard officers used excessive and disproportionate force against demonstrators who were passively .

Ball mill

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Copyright © .CMichineAll rights reserved.خريطة الموقع