- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Coal – Consulmet

Our Coal wash plants use highly scaleable robust process technologies. 1. Dense medium cyclone and spiral circuits are standard technologies for washing. Consulmet can combine these with floatation circuits to provide a complete coal handling and preparation solution.

Coal handling plant in a thermal power generating station

Mar 28, 2021 · The belt further elevates the coal to the transfer point 7 and it reaches the crusher through belt. In the crusher a highspeed 3phase induction motor is used to crush the coal to a size of 50mm so as to be suitable for milling system. Coal rises from crusher house and reaches the dead storage by passing through transfer point 8.

Iron Ore,Production Process of Iron Ore,Iron Ore ...

Production Process of Iron Ore. Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill,Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer.

CSIRNML

The process of developing a model for crushing circuit and simulating it regularly will optimize the parameters affecting the circuit performance. ii) Dry beneficiation Process flow sheet was developed for reducing ash in noncoking coal for appliion in thermal power .

track mounted stone crusher second hand dealer in india ...

Mobile Crushing Station Coal Crushing And Screening Plant Crusher For Sale. ... River stone processing plant, river stone coarse River Stone processing flow At the plant, raw river stone will be fed into jaw crusher for primary crus.... Learn More. Contact Me.

Steven Neilsen

Calibration and set up of Flow control valves, knife valves. Commissioning Electrical and Instrumentation on Iron Ore Processing Plant. Strong commitment to safety and team work. HV motors and HV VSD. LV motors and VSD's Hydraulic Packs, cooling Fans, lube pumps, switch gear, Soft Starters, large process water pumps, Rakes,

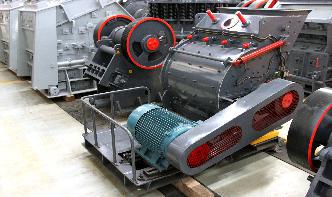

Crushing

An optimal crushing process reduce the ore to a desired size more efficiently, economically and safely. The highcapacity, reliable and energy efficient crushing solutions deliver superior performance and maximized throughput also for the most demanding mining appliions.

Optimal control of operation efficiency of belt conveyor ...

Jun 01, 2010 · Between C6 and C7, there is a coal crusher. Each boiler has six coal bins. The total capacity of the 12 bins is sufficient to sustain the two units for h under rated loads. Download : Download fullsize image; Fig. 1. Process .

Optimal energy control of a crushing process based on ...

Jan 15, 2016 · Cost saving discussion. Although the feasibility of both control strategies are technically proved through simulation results, it can be seen from Fig. 5, that the current control strategy runs the VSI crushing process without consideration of the TOU electricity this, the load (coal flow rates) is almost evenly distributed across the 24 hcontrol horizon without shifting ...

global website

Flow Control has become a separately listed independent company called Neles. Neles is a flow control solutions and services provider for oil and gas refining, pulp, paper and the bioproducts industry, chemicals, and other process industries.

Sipho Mahlangu

Extraction, crushing and screening or Ore in the heart of Sierra Leone. Landmarked by a overland conveyor that carries product from mountain tops to processing plant. Commissioning of 33kV ABB switchgear, Emerson Control Technique VSD's and MCC's. Designing primary crushing plant as well as primary scrubber and slurry thickener.

OptiDrive for AFC

The VSD is integrated with the motor to achieve better speed and torque control, resulting in softer starts/stops and faster acceleration. The variable chain speeds that match production conditions allow for increased capacity, improved cutting cycles, and greater efficiency for your longwall system.

Agus Hermansyah

Coal, dust nickel ore equipment. Process flow PIPFD diagram, diverter gates, splitter valves, coal grinding crushing, loading spout, hot fresh water piping. Smart Plant Materials MTO. Xstrata Strathcona, Sudbury (Oct 08 – Apr 09) Strathcona Mills Project. Slurry pumping system. TSSA registrations. Show more Show less

Five stages of gypsum production process | Stone Crusher ...

Jan 15, 2012 · Gypsum production process. Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant. Asneeded, the stockpiled ore is further crushed and screened to about 50 millimeters (2 inches) in diameter. If the moisture content of the mined ore is greater than about weight percent, the ore must be dried in a rotary ...

Coal Milling Machine Using Motor And Drive For Control

mv variable speed drive for coal mill capacity ... ... Inside of the ... revealed by the complexity of the control of the grinding process .... Current spectrum of a motor driving a coal ball mill from ... method for the monitoring of the machine based on the. ... VSD. Textile mills cannot work well without airconditioning ...

Copyright © .CMichineAll rights reserved.خريطة الموقع