- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

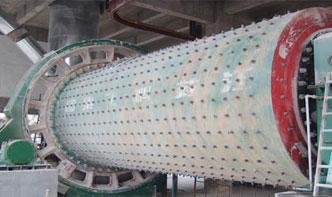

Ball Mill

Nov 18, 2008 · We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill. 6. 1. Introduction Ball mill is an efficient tool for grinding many materials into fine powder.

Ball Mill Loading

The starting point for ball mill media and solids charging generally starts as follows: 50% media charge. Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or decrease the free space) 50% x 26% = 13% free space. Add to this another 10%15% above the ball charge for total of 23% ...

Design and analysis of ball mill inlet chute for roller ...

Aug 26, 2014 · The present work is aimed at further understanding of the design studies of feed chute for powdery feed material and truck using FEM and DEM software and to use in the further designs of ball mills. FLS UMS Type Cement Ball Mill In 1893 FL (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventor.

Nurhabieb Adi Putra

Pipe Racks, Primary Concentrator Plant, Secondary Concentrator Plant, Ball Mill House, Transfer Tower, MCC Control Building, Vertimill Foundation, Tanks, Foundation, Ponds, Primary Road design Primary and secondary road design using flexible pavement ( flexible asphalt pavement, 10 m width), designed to bear traffic up to 50ton vehicles.

Low Alloy Steel Ball Mill Liners Design | Wear Parts For ...

Jul 09, 2020 · The low alloy steel ball mill liners studied in this paper have high hardenability and high tempering stability. After quenching at 850930 ℃ and tempering at 200290 ℃, finely tempered lath martensite is obtained, which makes the steel have high strength, high toughness and high wear resistance. The higher the hardness, the smaller the ...

ia design of ball mill

Apr 11, 2015 · ia design of ball mill 1. BinQ Mining Equipment ia design of ball mill, Ball Mill Design Specifiions, Quartz Ball Mill Design India, coal crushing ball mill design, Ball Mill Cover Design, agitator design for vertical ball mill, ball mill design .

diaphragm design of cement ball mill

ball mill diaphragm design. The diaphragm arrangement in a ball mill is a positive means of pumping pulp or dry material out of the mill The gradient is steeper than in an Overflow type mill A Diaphragm ball mill has a higher capacity and requires more power than an Overflow ball mill of equal ball .

Hydrocyclone Design Calculation

Cyclone Design Tool Ball Mill Design Calculation and ... Ball Mill Design Calculation Xls And PDF File; Mobile Crushing Plant. Leave a Message. ... hydrocyclone design ball mill circuits where society/organization is .

How to Choose the Right Ball Mill Manufacturers?

Sep 14, 2020 · 1. The innovation ability of the ball mill machine manufacturers. In general, whether an enterprise can go for a long time depends on whether the enterprise has the ability to research and development capabilities. Design and research the new ball mill is the foundation to support the development of the ball mill machine manufacturers.

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

Ball Mill Foundation Ball Mill

Ball Mill Foundation Design Mining Prominer Shanghai. Ball mill foundation design ball mill structural design gpgeoserviceit ball mill foundation design mill development and operations planenergy mines and high pyrite and low pyrite tailings dewatering and handling designs ball mill wikipedia a ball mill is a type of grinder used to grind and ...

Drawings Of Ball Mill | Crusher Mills, Cone Crusher, Jaw ...

ball mill,ball mills,ball mill machineHenan Bailing . For the foundation design and construction of ball mill machine, you can refer to the general assembly drawing and foundation drawing of ball mills equipment.

Lime Slaking Systems

Westpro's Ball Mill lime slaking design provides excellent slaking of lime while discharging no grit. Our system ensures the finest particle size by recycling coarse particles for further grinding. ADVANTAGES. Safe, simple, and trouble free operation. No practical upper limit for capacity.

Literature Review: Gearless Motor Failures – A Mill Designer's .

Sep 10, 2014 · The structural design of mills is much simpler than the structural design of ring motors. Most of the complexity in a mill is related to bearing design. However, Svalbonas restricts himself to structural design in his comparison of mills and ring motors in [1]. The rotating element (the shell, heads and trunnions) of a mill is a slowly rotating ...

Coal Mill

The control loop for mill outlet temperature discussed here is mainly for TT boilers based on a CE design with bowl mill (refer to Figure VIII/). A similar loop is valid for a ballandtube mill, which is discussed separately in the next section.

Make a Ball Mill in 5 Minutes : 4 Steps

Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use in paints, pyrotechnics, and ceramics." Many instructables refer to United Nuclear Ball Mills. Their small ball mill cost between 70 and 80 dollars. For no more than 30 and in 5 minute you can build a ball mill of appreciable performance.

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with .

Wet Grid Ball Mill

Wet Grid Ball Mill |. Capacity: Feed Size: ≤25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm. The effect in this job is better ...

Ball Mill Foundation Design

Ball mill foundation design 19 aug 2013 design of ball mill foundationspdf description vibration of the ball mill foundations design criteria ball mill design ball mill wikipedia a ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Kotchergenko Engenharia

Design of metallic structures for the replacement of four ball mills at the processing plant. Calculation and design of foundation for ball mill. LLX Structural and mechanical analysis of port equipments, ship loaders, wagon tippler, belt conveyors, transfer houses.

Ball Mill Parameter Selection Calculation

Aug 30, 2019 · 1 Calculation of ball mill capacity. The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting. There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of ...

Ball And Sag Mill Foundation Design Canada Crusher

Ball Mill Foundation Design In Canada. Apr 28 2012 our sagag ball and rod mills include fullertraylor mills the most robust design in the industry with installations up to 25ft in diameter in smaller mill sizes fl has a more costeffective mill line called the ft series with mills ranging in .

Ball Mill System – KHD Humboldt Wedag

Ball Mill System. Compact and efficient! KHD Humboldt Wedag mills are spacesaving, compact, high on performance and low on maintenance. This is primarily due to the support bearing design and the mill drive used. The mill is shellsupported, mounted on slide shoe bearings at both ends and made completely as a welded design.

Copyright © .CMichineAll rights reserved.خريطة الموقع