- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

DEA1

Process for the calcination of hydrated alumina in a kiln at a mean temp. of , opt. in the presence of calcination aid, operates kiln using a burner supplied with mixt. of oxygen and natural gas. The oxygennatural gas mixt. is stoichiometric, the kiln is a rotary kiln, and the hydrated alumina which is calcined, has a sodium oxide content of wt.% and a water .

USA1

A method of calcining an electrode material using a rotary kiln comprising a heat treatment section which has a cylindrical kiln shell, a supply section for introducing a process material into the kiln shell, and a discharge section for discharging the process material from the kiln shell, wherein the method comprises: introducing particles of the electrode material into the upper part of the ...

COMBINED CALCINATION AND CO2 CAPTURE IN CEMENT .

temperature to perform calcination, and rotary kilns are already in use in the cement industry, hence can be regarded as wellknown technology. It is possible to integrate the electrified calciner with an existing cement kiln system in such a way that minimum disturbance of the production process is obtained. Hence, no negative impacts on the process, product quality or emissions .

Petroleum Coke Calcining Systems

While calcination cannot improve upon certain quality limits inherent in the green coke, potential quality can be lost by improper calcining. How it works. Coke calcining plants can be loed in oil refineries, captive plants in aluminum smelters or merchant plants. Rotary Kiln The petroleum green coke is fed into a refractory lined rotary kiln where the volatiles are driven off during the ...

Calcination of calcium carbonate based materials in ...

Calcination reaction, lime uses, kiln types and CO2 emissions and emission reduction methods are discussed. Electric heated kiln concept and its advantages and downsides compared to traditional kiln technologies are presented. Additionally, heat transfer in electric heated kiln is studied. Literature review shows that the main difference of process conditions in the electric .

Characteristics and appliions of flash metakaolins ...

· Rotary kiln calcination is one of the most common processes used to produce commercial MK (Argical M 1000 in France, Whitemud in Canada, Metacaulim in Brazil, and others). The installation is similar to the kilns used for cement production, although it is operated under different conditions. The kiln is a cylindrical vessel, slightly inclined from the horizontal, which is rotated slowly about ...

Calcination of Limestone – IspatGuru

· calcination, lime, limestone, Long rotary kiln, preheater, reactivity, Rotary kiln, vertical kiln, Calcination of Limestone . Calcination or calcining is a thermal treatment process to bring about a thermal decomposition. The process takes place below the melting point of the product. The name calcination is derived from the Latin word 'Calcinare' which mean to burn lime. Lime (CaO) is one ...

petroleum coke calcination and not calcination honduras

· Cement rotary kiln Rotary calciners, also commonly called indirect kilns, are used in thermal processing operations where exhaust gases must be minimized, when processing finely divided solids, or where temperature must be tightly controlled along the length of the kiln. Petroleum Coke Predel Major Reference Works . Calcination ...

Factors Affecting Calcination Quality of Rotary Kiln ...

· One of the factors that affect the calcination quality of electric rotary kiln is temperature. Generally, the temperature of calcination zone should be controlled at ℃. 2. In addition, the main factor affecting the calcination temperature is the combination of fuel and air. The size of negative pressure. The amount of feed and the speed of material .

USB1

A rotary kiln for calcination of light aggregate cement comprises a calcination kiln body, a heavyoil combustion device, and a cooling device, wherein the calcination kiln body is formed in a Uturn for saving construction site and is composed of a feeding entrance at its upmost end, a product exit at the lowest end, and a plurality of revolving segments varied in caliber by segment so as to ...

CB01

predominantly in rotary kiln calciners, results in a further increase in SO2 emissions and the higher the GPC sulfur level, ... for calcination trials in a fullscale rotary kiln. 5. Full Scale Rotary Kiln Trials Several 410 ton batches of ACP from different green cokes sized to were produced and calcined in a full scale rotary kiln at the Rain Carbon Lake Charles calcining plant in ...

The Role of the Calciner in the Extraction of Lithium from ...

3D Model of a FEECO Directfired Kiln. Acid Roasting. Once the material has been decrepitated, or converted to betaphase spodumene (βform), an additional calcination step is required. The concentrate, now in βform, is first mixed with sulfuric acid (a step referred to as sulfuric acid digestion) and fed to a separate rotary kiln.

Calcination Brings Desired Qualities to Diatomaceous Earth

Upon mining, diatomaceous earth is milled and if necessary, dried in a rotary dryer, at which point it can be calcined. The calcination process is carried out in a rotary kiln (sometimes referred to as a calciner). Material is fed into the rotary kiln, which is typically of the directfired countercurrent configuration.

Modeling and simulation of petroleum coke calcination in ...

· The calcination of green petroleum coke in rotary kilns presents low operational costs due to the fact that the process is energy selfsufficient ( does not require fuel), and that it presents higher processing capacity compared to the conventional processes. Also, since it is a continuous process, stability in achieving a product with uniform quality is assured. A schematic diagram of a ...

Performance of Dolomite Calcination in a BenchScale ...

Corresponding author: winny Performance of Dolomite Calcination in a BenchScale Rotary Kiln Winny Wulandari*,1, Subagjo1, Anggoro Tri Mursito2, Fadly Junico Juanjaya1, and Muhammad ...

Industrial calcination of kaolinitic clays to make ...

· Clays are traditionally calcined in rotary kilns, although there are other technologies such as flash calcination and fluidized bed,, . However, many existing cement plants have a redundant, generally old, wetprocess clinker kiln that is used only when there is a contingency in clinker production. Such kilns could be retrofitted to produce calcined clays without any major .

Fluidized Bed Calciner | Zhengzhou DynNor Industrial ...

Fluidized Bed Calciner. Fluidized bed calciner provides best conditions for calcination of fine powders. It has unparalled advantages over other calcination system like rotary kiln, vertical shaft kiln,etc.. when it come to deal with powders. Fluidized bed is created when gas flows upward through a layer of powdery material.

Calcination furnace, Ashing furnace

MSE Rotary tube furnace is specially designed for the dynamic drying, sintering, calcination and other heat treatment of powders and granules and it is suitable for calcining of powders. The calcination... Compare this product Remove from comparison tool. calcination furnace ZTG series. rotary retort electric gas. calcination furnace. ZTG series... Working Principle: The .

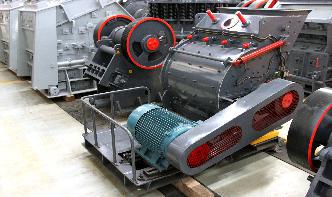

Structural advantages of rotary kiln

Rotary kiln is a rotating cylindrical vessel which is used for drying, calcination and sintering in a continuous process with the use of hot gases. The hot gases may be generated in an external furnace or by a flame inside the kiln. Our cement rotary kiln and lime rotary kiln has been developed for performing drying, calcination and sintering work in a continuous process. Widely used for ...

Cement kiln

Rotary kilns run 24 hours a day, and are typically stopped only for a few days once or twice a year for essential maintenance. One of the main maintenance works on rotary kilns is tyre and roller surface machining and grinding works which can be done while the kiln works in full operation at speeds up to rpm. This is an important discipline, because heating up and cooling down are long ...

CB05

The two 68 m long rotary kilns form the heart of the calcination process, but the plant features an extensive waste heat recovery and flue gas treatment system that generates electrical power from surplus heat. The system significantly reduces the impact of the calciner on the environment and enhances the sustainability of the operation. SO2 scrubbers remove most of the SO2 that would ...

Modelling and optimization of a rotary kiln direct ...

Modelling and optimization of a rotary kiln direct reduction process Kritzinger and Kingsley Hatch Goba Rotary kilns are used for a variety of mineral processing operations. Hatch makes use of a kiln model developed from first principles to evaluate designs for its clients. This tool has been applied to a variety of pyrometallurgical appliions. This paper illustrates the ...

Calcination Rotary Kiln | Calcination Plant

This highly engineered Calcination Rotary Kiln is exclusively designed to perform either endothermic (heat absorbing) or exothermic (heat liberating) processes. Our offered equipment is the best as this is quality tested under the stringent guidelines of our quality analysts. These low maintenance machines are used for the calcination of ...

Rotary Kiln For Gypsum Calcination

Factory Price Lime Calciner Rotary Kiln Manufacturer Factory price lime calciner rotary kiln manufacturer henan factory lime plant calcining gypsum rotary kiln 1 introduction of limestone calcination process active lime production line active lime kiln is a type of rotary kiln and it is the main equipment Oline Chat . Whatever your requirements, you 'll find the perfect serviceoriented ...

Copyright © .CMichineAll rights reserved.خريطة الموقع