- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

THE KEY LAKE PROJECT

MILL PROCESS In the process plant, the uranium is recovered from the feed ore with approximately % U 0 and concentrated to an 3 8 intermediate, semirefined product often referred to in the industry as "yellowcake" (with approximately 90% U 0 ). 3 8 The milling process at Key Lake is divided into five basic

Underground Milling of Uranium Ores

01/01/2007 · Cameco has studied the concept of underground milling of highgrade uranium ore. Compared to conventional milling on surface, the underground milling scheme appears to offer significant cost savings and a lower environmental impact. ... Other Asian countries, such as Vietnam and Indonesia, with large populations and rapidly growing economies ...

The Weekly DD

They are involved in the extraction of the uranium ore taken all the way to its enrichment where it will eventually be pressed into pellets and sold as nuclear fuel. This involvement includes 4 key steps: Mining and milling: the actual mining of the uranium. If it is mined as ore, this ore is crushed into powder. If it is mined as a dissolved liquid, then the uranium is extracted from the ...

ball mill uranium ore

I'm dealing with uranium ores in a lab scale ball mill (Bond Ball Mill). Much appreciated. Get Price. Part I Bureau of Land Management. Oct 24, 2014 ... E 5: Mining and Milling Technology, Methods, and .... administrators forecasted that a wave of uranium mining activity could ..... in a ball mill, screened, reduced to a slurry in a second ...

URANIUM ORE PROCESSING

NOT REACHED FULL APPLICATION IN MILLING OF URANIUM ORES (Session III) Stored technology for possible use in uranium ore processing (IAEAAG/337) 79 Seidel Discussion 89 PROCESS PROBLEMS AND DEVELOPMENTS FOR SOME NEW URANIUM ORE OCCURRENCES (Session IV) Notes on technical aspects of problems connected with .

Chemical Recipes: Uranium Extraction from Ore

13/05/2010 · Place the barrel on the mill and let it run for approximately 2 hours. This will reduce the ore into a very fine dust. This is necessary so the extraction chemicals will be able to react with the ore material. If Ball Milling is not done, very little Uranium will be extracted. After 2 hours of milling, the ore is as fine as Talcum powder.

Ball Mill Machine Iron Ore

30/01/2021 · A. Jankovic, in Iron Ore, 2015. Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Black Powder Manufacture

Black Powder MUST be made in a Ball Mill to work properly. A Ball Mill is a rotating drum with dozens of lead balls inside. The 3 chemicals are loaded into the Ball Mill, along with the lead balls, sealed shut and allowed to rotate for anywhere between 1 hour and 24 hours. As the Ball Mill rotates, the lead balls will crush the chemicals together, forcing some of the Potassium Nitrate into the ...

global website

Outotec is a frontrunner in sustainable minerals processing technologies, endtoend solutions and services globally. The company helps aggregates, mining, metals refining and recycling customers improve efficiency, productivity and reduce risks. Read more on Outotec website.

EPA Facts about Uranium

Uranium ore contains all the daughter elements of uranium238 and uranium235, but the uranium238, uranium234, and uranium235 are extracted and chemically separated during processing. This concentrated uranium product, which is generated at uranium mill tailing sites and uranium processing facilities, is a potential source of exposure to individuals and the .

Waste Guide for the Uranium Milling Industry

RAW MATERIAL URANIUM ORE Uraniumbearing ore, as it is delivered to the mills, may have a uranium content of from 0. 1 to 1 or 2 percent as UsOg, and generally averages about 0. 25 percent. This uranium is present as uranium238 and uranium235, both of which are naturally occurring radioactive parents of long chains of radioactive daughter ...

North Korea's Pyongsan Uranium Mill: Operations Produce ...

· The mill processed uranium ore from . The major difference was that the mill and waste tailings were loed on the same side of the river, such that no waste pipeline crossed the river. After closure, an attempt was made to remediate the waste tailings pile in place, but the potential hazards of groundwater pollution and potential of flood erosion led to a US government decision to ...

EPA Facts about Uranium

Uranium ore contains all the daughter elements of uranium238 and uranium235, but the uranium238, uranium234, and uranium235 are extracted and chemically separated during processing. This concentrated uranium product, which is generated at uranium mill tailing sites and uranium processing facilities, is a potential source of exposure to individuals and the environment and is a primary ...

Suggested rubber shell liners lifter bar thickness ...

i am designing rubber lining for ball mill with below given operating condition can you please suggest me approximate thickness of shell liners and lifter bar ? OPERATING CONDITIONS: 1. MATERIAL : MAGNETITE ORE + URANIUM ORE (COMBINED) 2

PT Freeport Indonesia

The ore mill processes ore from the mine by means of the following main concentrator areas: North/South Concentrators, Concentrator #3, and Concentrator #4. Processing design capacity (nameplate capacity) is described in brief (in 000 ton metric tons per day): Concentrator Title; Concentrator North/South: 60: Concentrator#3 (SAG #1) 60: Concentrator #4 (SAG#2) 115: .

URANIUM

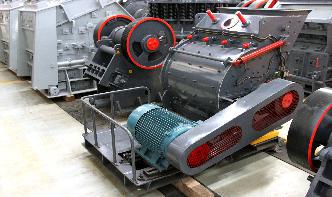

Ball Mills (Grinding Mill) Ball Mills (Grinding Mill) are used for size reduction to microns and form part of grinding circuit to get the final product for downstream Uranium Ore beneficiation by leaching. Thickeners. Thickeners are used to concentrate Uranium Slurry (3035% Solids) from refinery to about 60 70 % Solids. Overflow product is ...

Lumwana Copper Mine

Ore is reclaimed via apron feeders onto a conveyor belt providing direct feed, at a rate of about 2,500t/h, into the 38ft × 18ft SAG mill. The SAG mill trommel undersize discharges into a hopper and is pumped to conventional hydrocyclones, operating in closed circuit with a 26ft × 40ft ball mill. The hydrocyclone overflow (P80 of 280µm) reports to flotation, while the underflow returns to ...

Largest Uranium Companies in the World | Top Producers | INN

· While mining stopped at Ranger in 2012, the company is currently still producing material from stockpiled uranium ore. In 2019, Ranger produced a total of million pounds of uranium, which fell ...

Prairie Snapshot: Eight companies with potential in ...

· The mill tolls uranium ore from the Cigar Lake mine and was shut down for four months earlier this year to correspond with production stoppage at the mine. The mill .

Estimates of Electricity Requirements for the Recovery of ...

Estimates of Electricity Requirements for the Recovery of Mineral Commodities, with Examples Applied to SubSaharan Africa . OpenFile Report 2011–1253

Mining industry and sustainable ...

· Generally, the uranium ore extracted from the mine is processed by an associated mill order to obtain yellow cake (uranium oxide) for export (Fig. 10). This mining and milling stage generates significant amounts of mining waste and radioactive waste tailings, where most of the radioactivity of uranium ore due to uranium radioactive daughters will remain. These uranium tailings create ...

New Uranium Mining Projects

An armenianrussian joint venture for the mining and milling of uranium ore on Armenian territory is to be founded in the first half of 2008, according to Armenian minister of environment Aram Arutjunjan. During the Soviet era, the Armenian uranium resources were estimated at 30,000 t. (RIA Novosti Dec. 25, 2007) Russia and Armenia have signed an agreement on .

Uranium Chemistry | Special Nuclear Material

· I tend to put in about 5 lb of balls to 5 lb of crushed ore. A day's worth of milling turns most of the charge into powder that passes my kitchen sieve. Leaching uranium can be done with acids, or with carbonates. In industry, the choice depends on ore chemistry. Acid is uneconomical if the ore has lots of carbonates in it, but acid is more ...

China's Nuclear Fuel Cycle

Uranium ore bodies are mostly in area of 200 sq. km hosted by fluvial sandstones in the Zhiluo Formation as a regional redox front, and to a lesser degree within the Yan'an Formation, which has coalbearing strata. Individual tabular and rollfront ore bodies are several tens to one hundred metres long, up to 20 m thick, and have average ore grades of to %U. They plunge from 75 to 185 ...

Copyright © .CMichineAll rights reserved.خريطة الموقع