- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Process Of Iron Ore Dressing

Iron Ore Dressing Process Research. Iron Ore Dressing Process Research. Extraction of Iron from its ores, Iron dressing, Reduction. 23/10/2018· The ore dressing The aim of ore dressing is increasing the concentration of iron in the ore by removing the unwanted impurities and improve the properties of the ore which helps in the successive stages of extraction, The ore dressing process is ...

XRay Fluorescence Analysis of Iron in Ore Dressing Processes

16/08/2006 · The investigation of iron using off line energy dispersive Xray fluorescence, in iron ore dressing process, is presented. Techniques have been developed to determine the quality control of grinding, homogenization, separation, classifiion processes and residue material in dry basis of iron deposit. The laboratory trials on a wide variety ...

iron ore dressing process server|

iron ore dressing process server,The present invention relates to ore dressing process for siderite, limonite and other weakic iron ore. Siderite, limonite or other weakic iron ore is made to pass through theizing and roasting,ically separating and reverse floating process in a rotary kiln to obtain concentrated iron ore...

iron ore dressing process research

iron ore dressing process research Abstract: Iron ore and tin mineral are the mainly recovered minerals of the lowgrade ore, which could be effectively separated by a strong magnetic separationgravity concentration process, with ore iron grade of %, tin grade %.

Iron Ore Analysis Process Optimization Solutions ...

To efficiently process iron ore for high quality steel production, frequent ore grade monitoring, during all steps of downstream processing, is mandatory. Independent from the ironmaking method, the optimal use of fuels and energy during sintering, pelletizing and direct reduction of iron ore (DRI) needs to be applied to stay competitive and ...

Research on Exploration of Mineral Processing for a Iron Ore

Iron ore minerals are mainly silietype iron minerals in raw ore, and its distribution rate was %; followed by magnetic iron, and its distribution rate was %; content and distribution rate of other minerals was very low; element grade of iron, phosphorus, sulfur, silica were %, %, % and %, the main gangue were silica and calcium oxide, .

Research on Exploration of Mineral Processing for a Iron Ore

Iron ore minerals are mainly silietype iron minerals in raw ore, and its distribution rate was %; followed by magnetic iron, and its distribution rate was %; content and distribution rate of other minerals was very low; element grade of iron, phosphorus, sulfur, silica were %, %, % and %, the main gangue were silica and calcium oxide, recyclable iron .

iron ore dressing techniques

Separation Method Of Iron Ore Dressing Physically. Possibility of using magnetic separation methods to produce iron ore concentrate that could be used as a processed Ajabanoko iron ore recovered from the process Get Price iron ore dressing process research . iron ore dressing process research. conventional physically based beneficiation methods .

iron ore dressing process research

Iron Ore ScienceDirect. Iron Ore Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its production.

dressing process in iron ore

Extraction of Iron from its ores, Iron dressing, Reduction. Oct 23, 2018· Extraction of Iron from its ores. Extraction of iron or its metallurgy is the process of obtaining this metal in a form where it can be put to practical use, and this process of extraction consists of three stages: Ore dressing, Reduction of ores and Iron production ...

Mineral Processing

20/09/2021 · Mineral Processing Science topic. The processings of ores for mineral recovery and extraction of metal values. Froth flotation, .

process of iron ore dressing

process of iron ore dressing_Mineral processing WikipediaIn the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their ... iron ore dressing process research ...

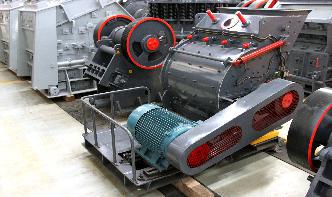

Hot Sale Products iron ore dressing process research

iron ore dressing process research; Hot Sale Products iron ore dressing process research. As one of the leader mining and construction equipment manufacturer in China, AC Machinery has participated in many turnkey plant in Asia countries. We are experienced in cement plant, crusher machine plant, quarry plant, powder production line ...

Mineral dressing (= Orebeneficiation)

Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate ...

Iron Ore Dressing Process Research

Iron Ore Dressing Process Research. Mineral processing Wikipedia OverviewHistoryUnit operationsOther processesSee alsoNotesSources. Before the advent of heavy machinery the raw ore was broken up using hammers wielded by hand, a process called "spalling". Before long, mechanical means were found to achieve this.

Copyright © .CMichineAll rights reserved.خريطة الموقع