- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Construction And Operation Of Ball Mill

ball mill operation construction material in uzbekistan. ball mill operation construction material in uzbekistan. Ball Mill Operating principles components Uses,The balls which could be of different diameter occupy 30 50 of the mill volume and its size depends on the feed and mill size The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product ...

construction of ball mill

Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. Get price. The Purpose Of Ball Mill In Construction PurposeOf. Jul 22, 2014 · On the construction sites, usually large or .

Construction Of Ball Mill

Material Construction Of Ball Mill In Plant Machinery. ball mill operation construction material ball mills planetary ball mill korea crusher plant there are two ways of ball mill grinding the dry way and the wet way it is used to grind many kinds of mineral ores and other materials or to select mine professional cement ball mill for ...

Construction Of Ball Tube Mills

Ball and tube mills Mill construction details Operation The significant use of ball mill in thermal power plant ppt pressurized double ended ball tube mill bbd 4760. Prices / Quote End Mills Solid Carbide Construction Reamer Custom

The operating principle of the ball mill

· The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed ...

Hazards Identifiion and Risk Assessment in Thermal ...

rocks pass out to the bottom of mill and transfer to the clinker grinder then to the storage. B. Plant Raw water is demineralizing to free water from salts and ions then treated with sulphuric acid and caustic soda to retain the ph level up to 9. This process is done in the demineralization plant. Demineralized water transfers

Working And Construction Of Ball Mill

Ball Mill Working And Construction. Construction And Working Of Ball Mill Joyal Ball Mill Tractor Construction Plant Wiki The ball mill is widely applied in mineral classifiion cement fireproof materials glass pottery chemical industry and so on The ball mill can grind all kinds of rocks and grinding materials There are two ways of grinding the dry process and the wet process Working ...

How can one select ball size in ball milling and how much ...

· There should be atleast 25% empty place in the milling jar after feeding balls and the material while high energy impact. There is no such thumb rule for powder to ball ratio.

construction of ball mill

Construction And Working Of Ball Mill. Joyal Ball Mill Tractor Construction Plant Wiki . The ball mill is widely applied in mineral classifiion, cement, fireproof materials, glass, pottery, chemical industry and so ball mill can grind all kinds of rocks and grinding are two ways of grinding the dry process and the wet .

rodmillor ball mill construction

construction material in ball mills Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Supertech International

Welcome To. Supertech International. We are engaged in manufacturing, exporting and supplying various range of cement plants, grinding units, ball mills, etc. We are known for the features like durable construction, high performance and longer service life. The most updated technologies adopted highly experienced professionals employed and large .

Practical 1 : Ball Milling | TF Lab 1

· Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A ball mill is a type of grinder which consists of a cylinder. It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. The cylinder rotates around a horizontal axis.

Ball Mill Operation Construction Material

Ball mill operation construction material. ball mill operation construction material,a grinding mill is a unit operation designed to break a solid material into Mill BallGrinding Ball MillsCeramic Ball MillCement Ball In accordance with city construction, Ball Mill The rubber lined ball mil are mainly mine and other materials.

Industrial Ball Mills: Steel Ball Mills and Lined Ball ...

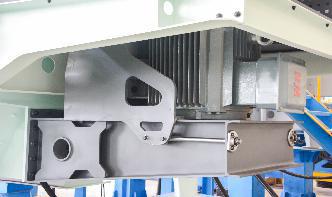

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or .

Ball mill

· Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is approximately equal to its diameter Balls occupy about ...

Effect of ball and feed particle size distribution on the ...

· The ball mill, liners and grinding media employed were made from stainless steel. This material of construction is superior over all else because of its durability and resistance to wear and tear. It is due to these reasons that contamination of the material was ruled out.

Ball Mills

In general, ball mills can be operated either wet or dry and are capable of producing products in the order of 100 μm. This represents reduction ratios of as great as 100. Very large tonnages can be ground with these ball mills because they are very effective material handling devices. Ball mills are rated by power rather than capacity.

Construction Of Horizontal Ball Mill

Construction and working of ball mill calculation pdfod mills operate at lower speed than ball mills since the rods are rolled and not cascaded for an equivalent grind, a rod mill uses less steel than a ball mill because of the lower speed and better contact between the media and ore the rod charge must be maintained in good working condition, and broken and worn rods must be .

Construction Of Ball Mill

Construction Of Ball Mill. May 22 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated the grinding body ball and the object to be polished material installed in the cylinder are rotated by the cylinder under .

Copyright © .CMichineAll rights reserved.خريطة الموقع