- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Coal Plants | Replacement wear parts for coal power ...

Unicast supplies costeffective parts for coal plants, such as replacement wear parts for hammermills, roller and ball mills, feeders and rotary breakers. Find .

Coal Mill In Cement Plant, Airswept Coal Mill | Coal Mill

The coal mill adopts an edge driving system, is driven by the motor through the reduction gear and large and small gears. Raw coal is fed into feeding device of coal mill in cement plant, the hot air with temperature about 300 ℃ through the duct into the feeding device, there is a special lifting board in drying storehouse board will raise the raw coal, and helps the raw coal .

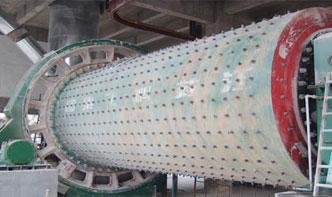

COAL PULVERIZER_ZK Ball Mill_Rotary Kiln_Grinding Equipment

Coal pulverizer is a mechanical device used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants. Coal pulverized machine is the ideal powder making equipment in electric power industry, metallurgy industry, chemical industry, building construction, coal industry, fireproofing materials making industry and some others.

Pulverized Coal Preparation Production Line_ZK Ball Mill ...

raw coal from storage and conveying system come into air swept coal mill for grinding. The coal powder mass and heat transfer with 200℃~350℃ hot air. The moisture enter into flue gas from coal. Coal powder is dried by hot air. Then coal powder come to powder separator with airflow for classifiion.

Technical parameters of vertical grinding of 1300M(coal ...

(coal) (Hardgrove index >55) 6. Maximum feeding size: Max = 40mm 7. Type of motor (separator): Y225S8 (frequency conversion speed regulation). 8. The speed of separator: 140 ~ 229r/min 9. Hot gas temperature entering the mill: ≤300°C 10. End product temperature: 90°C 11. Feeding water content: less than 15% 12. Grinding material ...

Cement Mill Dynamic Separator Principles

dynamic separator working principle with cyclones in. cement mill is mainly used in the cement silie product production principle the raw coal goes into the feeding device of the grinding separator for coal mill is mainly used as the separation equipment in of the cyclone collector and go to the next ...

Dry Coal Processing Plant Rotary Breaker And Screener

mill rotary separator in coal pulveriser Sand Making Plant. Gypsum Powder Crushing Plant Slag Crushing Processing Amphibolite Crushing Plant Bentonite Ball Mill ... plant mill rotary separator in coal pulveriser in india. ...

coal drying Equipment | Energy XPRT

Photoelectric intelligent dry type coal separator is a kind of dry type coal separation equipment based on advanced imaging and artificial intelligence technology. ... Hammer mills are used to dry and grind coal, dry and grind gypsum, dry and grind dolomite ... Rotary drum dryer supplier in China with diameter x 12M to x 28M, ...

Mitsubishi Rotary Separator Mill

A vertical mill for material such as cement raw materials, clinker, coal, ... their rolling on a rotary table, a separator means which is positioned above ... 2008, Feb 25, 2014, Mitsubishi Heavy Industries, Ltd. Roller mill structure.

China High Running Rate Rotary Dryer for Coal

China High Running Rate Rotary Dryer for Coal, Find details about China Raw Coal Rotary Dryer, Coal Dryer from High Running Rate Rotary Dryer for Coal Henan Zhengzhou Mining Machinery Co., Ltd.

Coal Plants | Replacement wear parts for coal power ...

Unicast supplies costeffective parts for coal plants, such as replacement wear parts for hammermills, roller and ball mills, feeders and rotary breakers. Find content on our website

coal mill in cement plant pdf

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination.

mitsubishi rotary separator mill

rotary separator in coal mill. rotary coal seperator for coal mill Mill Rotary Separator In Coal Pulveriser, capacity coal pulverizers which use MHI's advanced Mitsubishi Rotary Separator to .Johnson SelfLeveling CrossLine Laser LevelCoal pulverizer is one advanced mill, adopting top technology domestic and, coal pulverizers which use MHI's advanced Mitsubishi Rotary .

Lignite Coal DryerRotary kiln,rotary dryer_Hongke Heavy ...

Lignite coal dryer allows the moisture content of lignite evaporated at a lower 13% by adopting low temperature four class drying process without changing the quality of dried lignite. Lignite coal dryer, also known as lignite rotary dryer, brown coal dryer or coal ash dryer, is suitable for granular materials and can also be partially put into ...

Rotary Kiln Manufacturers | Electrotherm ET

Coal Based Rotary Kiln for Direct Reduced Iron / Sponge Iron (100 TPD, 350 TPD, and 500 TPD) Solidstate reduction of Iron Ore using either coal/gas as a medium of reduction to produce a substitute raw material for steel making is termed as Direct Reduced Iron (DRI). Since DRI is produced by removing oxygen from iron ore, its structure is just ...

coal mill rotary classifier

coal mill rotary classifier. Product specifiion: Processing capacity: 18010,000t/d Processible materials: roasting cement clinker in the industries of metallurgy, refractory matter and chemical plant . Appliion range: industries of construction materials, metallurgy, chemical engineering and environment protection. Advantages: advanced preheating system, high rotary speed, .

ball mill coal mill separator

RTKM separator – for coal grinding ball mills. designed for use with ball mills that grind coal, petcoke or charcoal. It is an energyefficient and wellproven solution which incorporates the experience attained from over 1500 high efficiency dynamic air separators supplied by FL in grinding appliions.

Vertical Coal Mill

The raw coals after iron removal by electromagnetic separator are put into the warehouse for storage. 2. After grinding system has started, please turn on the rod valve in the bottom of raw coal storage, and start sealing measuring belt to coal mill, then raw coal will be dryed and ground in the vertical coal mill. 3.

Copyright © .CMichineAll rights reserved.خريطة الموقع