- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

Electromagnetic separation is used in the concentration of

COMEDK 2005: Electromagnetic separation is used in the concentration of (A) copper ore (B) tin ore (C) silver ore (D) aluminium ore.. Check Answer and

Use of Gravimetric Separators for the Beneficiation of ...

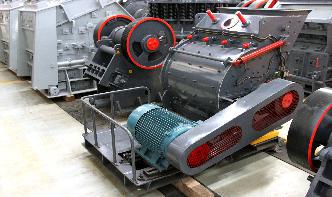

Vol. 22, No. 3 (2010) Use of Gravimetric Separators for Gunduzler Chromite Ore 2419. General procedur e: The whole sample w as cr ushed belo w 15 mm using a ja w crusher . The crushed ore was split to 3 subsamples b y using a sample splitter . The first sample was classified into different size fractions by screening to use in the first group of concentration tests. The .

A discussion of magnetic separation techniques for concentrating .

WHIMS or conventional gravity concentration. As an example, recovery of hematite and ilmenite fines with SLon® technology is now practised widely throughout China. It is also being piloted by many mineral sands producers worldwide, both to replace prior art WHIMS and as a potential intermediate step between traditional WHIMS and dry magnetic separation. DOBBINS, M., .

Beneficiation of Iron Ores

· Jigging – Jigging is a gravity concentration technique where the iron ore is separated into light density fraction, medium density fraction and heavy density fraction. Size fraction of the iron ore used for jigging is mm to 30mm. Spirals – Spiral concentrators are flowing film separation devices. General operation is a continuous gravitational laminar flow down on an inclined surface ...

gravity separation used to concentration of which ore

Concentration of the ore gravity separation. concentration of ore by gravity separation method and youtube nov 13 2012 this video tell you the various techniques used to concentration of ore this video will also describe the process of it get price and support online gold concentration of minerals google sites. Effective Processing Of Low . The most commonly used beneficiation methods for iron ...

Ores and Minerals

The removal of matrix or gauge from the ore is called concentration ore. Several steps are involved in the extraction of pure metal from ores. Below is given a flow diagram of various steps involved in extraction of metals – Concentration of Ores . First ores are crushed and grinded and then gauge or matrix is removed from the powdered ore. This is called concentration of ores. .

Ore Mineral Concentration ...

Gravity separation is a longstanding beneficiation method. Due to its simplicity, low cost, and growing development, the gravity separation method is still the main beneficiation method for tungsten tin ore and coal. It has also been widely used in the selection of certain nonferrous metals, ferrous metals, precious metals and nonmetallic ores.

Use of Gravimetric Separators for the Beneficiation of ...

Vol. 22, No. 3 (2010) Use of Gravimetric Separators for Gunduzler Chromite Ore 2419. General procedur e: The whole sample w as cr ushed belo w 15 mm using a ja w crusher . The crushed ore was split to 3 subsamples b y using a sample splitter . The first sample was classified into different size fractions by screening to use in the first group of concentration tests. The second sample was ...

Which process is usually applied for separating gangue from .

Types of Separation or Concentration of an Ore Froth Floatation Method video tutorial 00:12:48; Advertisement Remove all ads. Question Bank with Solutions. Maharashtra Board Question Bank with Solutions (Official) Textbook Solutions. Balbharati Solutions (Maharashtra) Samacheer Kalvi Solutions (Tamil Nadu) NCERT Solutions; RD Sharma Solutions; RD .

How to Process Copper Ore: Beneficiation Methods and ...

· Magnetic separator for copper ore dressing Performance advantages of magnetic separator . 1. High technology. The internal magnetic system of the barrel adopts a short circuit design to ensure that the barrel skin has no magnetic resistance at high speeds, and the stainlesssteel barrel skin does not generate high temperatures, extending the life of the magnetic block. 2. High taste in the ...

Major Mines Projects | Namakwa Mine

The Namakwa Sands heavy mineral deposit at BrandseBaai was discovered in 1986 by Anglo American, who commissioned the integrated mineMSPsmelter project in 1995. Ore is excavated from two openpit dry mines and delivered by trucks and conveyors to two primary wet concentration plants. [2019 AR Form 10K, p. 33]

Solutions for Lithium Processing

from brine concentration to highpurity particles. A major Australian lithium producer has constructed a lithium carbonate plant in China using spodumene ore as a raw material. GEA has delivered the evaporatorcrystallizer that precipitates Na 2 SO 4 from the mother liquor containing lithium. Electrical energy for lower carbon emissions With global lithium reserves estimated to .

gravity separation used to concentration of which ore

Concentration of the ore gravity separation. concentration of ore by gravity separation method and youtube nov 13 2012 this video tell you the various techniques used to concentration of ore this video will also describe the process of it get price and support online gold concentration of minerals google sites. Effective Processing Of Low . The most .

1 Froth Flotation – Fundamental Principles

separation, the products are as shown in Table 1. Using this data, calculate: (a) Ratio of concentration (b) % Metal Recovery (c) % Metal Loss (d) % Weight Recovery, or % Yield (e) Enrichment Ratio Table 1: Grade/recovery performance of a hypothetical copper ore flotation process. Product % Weight % Cu Assay Feed 100

Metallurgy

Types of separation or concentration of an ore. There are four major types of separation of ores based on the nature of the ore. The different kinds of ores of metals are given in Table Concentration of the crushed ore is done mainly by the following methods: (i) Hydraulic (Gravity Separation) method . Principle: The difference in the densities or specific gravities of .

Copyright © .CMichineAll rights reserved.خريطة الموقع