- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

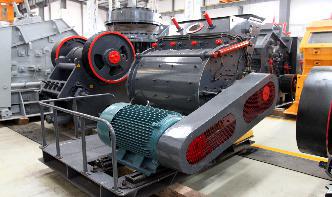

Combination Crusher

Combination crusher is one of the common equipment in crushing plant and sand making plant. it can be widely used in crushing raw materials, clinker of cement plant, also available in medium hardness materials fine crushing of dolomite, leadzinc mine, serpentine, blast furnace slag, coal, phosphate rock and so on. Combination Crusher Features: 1.

Clinker And Gypsum Crushing Mill Crusher

Clinker And Gypsum Crushing Mill Hp Kneis. Clinker and gypsum crushing mill 80t h120t h limestone requirement for 1 ton clinker small ball mill gypsum used to produce 1 tonne of cement gypsum is added to clinker primarily as an additive preventing the coating of the powder at the surface of balls and mill wall furnace slag with the portland cement clinker and gypsum are ground

Achieving the "Lowest Clinker Factor" | First Construction ...

For The Lab Ball mill grinding of average/spot clinker with fixed Time, it is preferable to select a grinding time to achieve Blaine's of around 300 320 M2/kg with the residue on 45 microns of the Cement in range of 18 to 20%, at this fineness, the clinker is observed to depict changes in clinker reactivity in terms of changes in 1 Day ...

dry grinding gypsum overview

DIAGRAM OF GRINDER USE IN GRINDING CLINKER WITH GYPSUM. Cement mill Wikipedia, the free encyclopedia Gypsum and calcium carbonate are relatively soft minerals, and rapidly grind to ultrafine aids Ball Mill Ball millLarge balls are used at the inlet, to crush clinker nodules (which can be over 25 mm in diameter).

Cement Production

The last step in cement manufacture is the grinding of clinker with additives. Grinding is done in different types of grinding equipment, such as a ball mill (see Figure 6) or in more efficient vertical roller presses; in a ball mill, the particles are crushed by the impact of steel balls.

Ball mill

Features. CHAENG energyefficient ball millequipment is new equipment to transform the basis of the traditional ball mill after, It changed the original mill structure, it is possible to reduce energy consumption by 30%, capacity increased by 1520%, it is widely used in cement silie products, new building materials, refractory materials, fertilizer, metal ore and glass ceramics etc ...

「grinding of clinker in ball mill in pdf」

Jan 24, 2019During the grinding of OPC clinker in lab ball mill, the grinding aids are added with the ratios 0,, and wt. % of the clinker with gypsum. A constant 10% of gypsum by weight of clinker has been added to each cement mixture with clinker factor 90%. A. Inquire Now; Clinker Grinding Ball Mill Media Charging Process Wikipedia

BASIC CEMENT PLANT LAYOUT – Process Cement Forum – The ...

Jul 04, 2020 · Ball mills are suitable for low and medium moisture content in the range of five to six percent and are preferred for abrasive material. ... 11/12 Clinker/Gypsum Storage . ... The storage may be of silo type or covered stacker reclaimer type or simply a gantry type. Silo type clinker storage has the advantage that there is no dust pollution and ...

Cement clinker

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilie materials such as clay during the cement kiln stage.

What is Cement Clinker? Composition, Types Uses

Types of Clinker. The most common type of clinker is produced for Portland cement and its blends. ... Gypsum added to and ground with clinker regulates the setting time and gives the most important property of cement, compressive strength. It also prevents agglomeration and coating of the powder at the surface of balls and mill wall. Some ...

Clinker Calcination | Datis Export Group

May 16, 2020 · After that, the raw mix will be sent into the ball mill or other grinders so that the particle size of the powder reaches a certain degree of fineness. The higher the grinding fineness is, the faster the reaction speed in the rotary kiln. Raw Materials Crushing, Storing and Grinding. Clinker calcination

Cement Production Line, Cement machinery, Rotary kiln ...

17 system Ball mill is the earliest grinding equipment used in cement production industry, and it still plays a leading role. Although its efficiency is very low, for example, the power consumption of single particle is only 6% 9%, the maintenance of ball mill is simple and reliable, especially for cement clinker grinding.

Cement Roller Press, Roller Press In Cement Plant

As newtype and energyefficient cement grinding machine, cement roller press has advantages of energysaving, high efficiency, less steel consumption and less noise. Both apply for new cement plant building and old cement plant revamping. According to the data, roller press helps ball mill system to increase the output by 3050%.

Resistance to Grinding and Cement Paste Performance of ...

Apr 19, 2021 · The resistance to grinding was expressed as a constant parameter (K R) in the model proposed by Rittinger for grinding fine particles and was found to be 56, 40 and 14 J mm/cm 3 for clinker, gypsum and limestone, respectively. Additions of limestone, gypsum or both materials to clinker had a lowering effect on K R. The interaction between each ...

Cement Mill

Clinker particles, gypsum, and other materials in cement grinding machine will be ground together into fine powder to match the fineness of the finished product. The cement grinding mill in a cement plant mainly includes cement vertical mill, cement ball mill, ultra fine grinding mill, cement roller press, etc. They are suitable for both wet ...

Clinker is pulverized and finely ground in tube ball mills ...

Clinker is pulverized and finely ground in tube ball mills and automatically from CHEMICAL E 100 at University of Jordan

Types Of Raw Mill

resources and raw material types for ball mill with gypsum . resources and raw material types for ball mill with gypsum and clinker. SBM is a professional ... Read more. main gearboxes type 1720 of raw mill Mill Plant.

Cement Grinding Clinker Mill Ball Mill Type

types of ball mill cement mill. Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for us. View Details Send Enquiry

The Most Valuable Things You Need to Know about Gypsum ...

Sep 02, 2021 · The ball mill is mainly a machine for dry or wet grinding of the crushed gypsum. The machine is mainly used for repeated grinding of the raw materials in the barrel through the steel ball medium in the ball mill to complete the ball grinding operation. Advantages of Fote ball mill. The ball mill can control the grinding time flexibly and reduce ...

Cement Clinker Grinding Plant

Cement clinker grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement newtype cement grinding units adopt pregrinding technology. The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of .

What is Clinker? (Meaning, History, Manufacturing ...

Clinker, joint with some additives and ground into a fine powder, is applied as a binder in cement goods. Diverse elements are added to attain precise properties in the formed cement. Added Gypsum to and ground with clinker controls the setting time and grants the most significant property of cement, compressive strength.

gypsum clinker grinding unit

Energy and exergy analyses for a cement ball mill of a new . The clinker grinding unit mainly consists of a ball mill and a dynamic separator that their technical information is illustrated in Table 1. The initial product is a mixture of clinker gypsum and limestone.

gypsum added and ground with clinker ball

Thu Working Of Ball Mill With Gypsum And Clinker . A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills and also vertical roller mills heat generated in the grinding process causes gypsum casoHo to lose . Read More

Ball Mill

Ball mill is the key machinery for further smashing broken materials. Ball mill is suitable for crushing various ores for rotary kiln. Ball mill is widely used in many sectors like mineral processing, building materials and chemical industry. Ball mill can be divided into dry type and wet type; According to different mine discharge types, it ...

Copyright © .CMichineAll rights reserved.خريطة الموقع