- 0086-21-58386258

- [email protected]

- No.416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China

- English

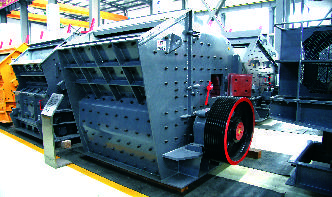

What Is A Hammer Mill Grinder How Does It Work?

A hammer mill grinder is designed to reduce bulk material into smaller pieces, either by crushing or shredding. They are an important machine in many industries, including the mining, lumber and waste management industries. However, it is most often found in grain processing facilities, as it can quickly reduce bulk grain to smaller pieces for ...

Key considerations when choosing a grinding machine

Grinding is traditionally known as a finishing process, the innovation of today now allows us to combine precision with much higher metal removal rates. Surface finish requirements go hand in hand with the degree of accuracy needed to be achieved so the demands of your grinding machine are much higher than a typical CNC mill. Rigidity / Harmonics

Grinding Machine [Grinding Wheel, Types, Operations, More]

10/05/2020 · The common grinding machine operation are surface, cylindrical, internal and centreless grinding. Now let us discuss each one by one, 1. Surface Grinding. It involves grinding flat surfaces. Here the workpiece is fitted with a magnetic chuck attached to a work table of the grinder.

Surface grinding with a milling machine

22/11/2008 · I came up with an idea to be able to surface grind on my milling machine using regular die grinding stones. Up to now I have used a flared cup grinding wheel but I have never been able to find them in a finer grit then 80. So I turned an arbor out of 4142 that will take the regular 1/4 shank die ...

Industry Grinder for Mineral Processing

Ball mill, also known as ball grinding machine, is a wellknown ore grinding machine, is widely used in mining, construction, aggregate start the ball mill business in 1985, supply globally service includes design, manufacturing, installation, and free operation training.

What is the best salt to use in a salt grinder?

5/02/2020 · The pepper grinder is made up of large and small grooves. One word of caution: You should never use salt in a pepper grinder or pepper in a salt mill. The salt will corrode the metal used in the grinding mechanism of a pepper mill and the metal in the salt mill is not hard enough for peppercorns.

INSTRUCTIONS HOW TO USE A MILLING MACHINE

MACHINE Milling is the process of machining flat, curved, or irregular surfaces by feeding the workpiece against a rotating cutter containing a number of cutting edges. The usual Mill consists basically of a motor driven spindle, which mounts and revolves the milling

Grinding Machines

Grinding machines, like broaching machines, operate over a range of speeds depending on the type of machine being range from approximately 1250 to 2000m min −1, although in highspeed grinding speeds of up to 5400m/min are achievable (Schey, 1987).The two most common grinding appliions are cylindrical grinding and surface grinding.

What Machining Accuracy Can Be Achieved By Turning ...

31/05/2019 · The machining accuracy of turning, milling, planer, grinding, drilling and boring are introduced. IT Standard Tolerance Level Table Note: When the basic size is less than 1 mm, there is no IT14 to IT18.

VMA

The actual dispersion system in a bead mill consists of a milling chamber and an agitator; the milling chamber is filled with the grinding beads (material glass, zircon oxide, steel) and the product to be dispersed. In the milling vessel, the grinding medium is kept moving by the agitator, which itself is driven by a motor.

Dental milling and grinding machine R5

The 5axis milling machine for nonstop dry and wet machining. With the R5 – a new highend machine for the dental laboratory – vhf has developed a highly automated milling and grinding machine that brings revolutionary approaches to the lab along with a tenfold blank changer for wet and dry machining.

What is a Milling Machine? (with pictures)

CNC machines are driven by computer aided design (CAD) programs which control most, if not all, functions, require minimal operator input. Generally, a milling machine operator runs the machine by feeding the material over a device called a milling cutter. As the material is fed past the cutter, the cutter's teeth slice through the material to form the desired shape.

Industrial Roller Mill | Roller Mill Manufacturer ...

Williams roller mills can perform simultaneous grinding and drying functions with one continuous operation. The roller mills simultaneous grinding and drying features are typically for materials with higher moisture such as limestone and clay. Learn more about the Williams machines capable of simultaneous grinding and drying functions.

Types of Workshop Machinery

Machine tools play an important role in a workshop thereby enhancing the speed, efficiency and accuracy of processes like cutting and shaping of harder substances like wood, metal etc. This article contains brief information on types of workshop machinery employed in metal and wood working appliions. Appliions of milling machine, grinding machine and shaping machine .

Hammer Mills

Wood hammer mills, also called wood hogs are special heavy duty Stedman Hammermills specifically designed to process wood and fibrous waste without the use of high maintenance knives. Our machines have simple designs with rugged construction that make them easy to operate and maintain. Additional Resources. Hammer Mill Operation and Maintenance.

What Is A Surface Grinder

The surface grinding machine is the most common type of grinding machine found in any shop. You can actually compare it to milling cutter that has multiple teeth but the surface grinding machine has a grinding wheel, which makes it an abrasive cutting tool.

What Does a Milling Machine Do?

21/04/2020 · There are plenty of other mill machine tools in many factories. Some notable examples include corner rounding end mill, keyseat cutters, carbide face mill, and Tslot cutter. To maximize the use of the equipment, metal fabriion companies often opt for knee type milling machines.

Machines | vhf Inc.

The gold standard for lab and practice. With the R5 – a new highend machine for the dental laboratory – vhf has developed a highly automated milling and grinding machine that brings revolutionary approaches to the lab along with a tenfold blank changer for wet and dry machining. Detailed information on the R5. Z4.

Milling machine | Britannica

12/10/2021 · Milling machines have rotating cutting surfaces that abrade substances with which they come into contact. In standard milling machines, a sliding table with a workpiece on top is pushed against the whirling cutter. Grinding machines function in a .

What's the Difference Between SAG Mill and Ball Mill

26/11/2019 · A mill is a grinder used to grind and blend solid or hard materials into smaller pieces by means of shear, impact and compression methods. Grinding mill machine is an essential part of many industrial processes, there are mainly five types of mills to .

Milling On A Grinding Machine | Modern Machine Shop

8/11/2005 · A grinding machine is not a machining center, but it can sometimes take on milling and drilling (or even turning) to make the overall process more efficient. This machine does the work of a grinder, a vertical lathe and a boring mill. Combining the work of three machines into one saves about six hours of setup time from the production of a ...

Difference Between the CNC Milling Machine and VMC Machine

6/09/2019 · CNC milling machines have only three axes, and CNC machining centers can be fouraxis or fiveaxis linkage, which is more widely used than CNC milling machines. The CNC machining center is a CNC machine tool with an automatic switching device and continuous processing in multiple processes. It is developed from CNC milling machines.

What is a Grinding Machine? (with picture)

These machines can be used to grind complex shapes and holes with a high degree of accuracy. Jig grinders typically operate using a removable, highspeed air spindle to rotate the grinding bits. Whether the speed of a jig grinding machine is fixed or adjustable varies from one machine to another.

What is Abrasive Machining?

1/02/2010 · Abrasive machining is not considered to be a precision grinding process, but that's not to say it isn't precise. Abrasive machining can take the place of "largechip" machining processes like milling, planing, broaching, and turning. Compare the surface finish and the precision achieved with the largechip processes to the surface ...

Copyright © .CMichineAll rights reserved.خريطة الموقع